Search

Search

We seek to meet the standards required by our stakeholders and customers so they can be confident of traceable, responsibly sourced products.

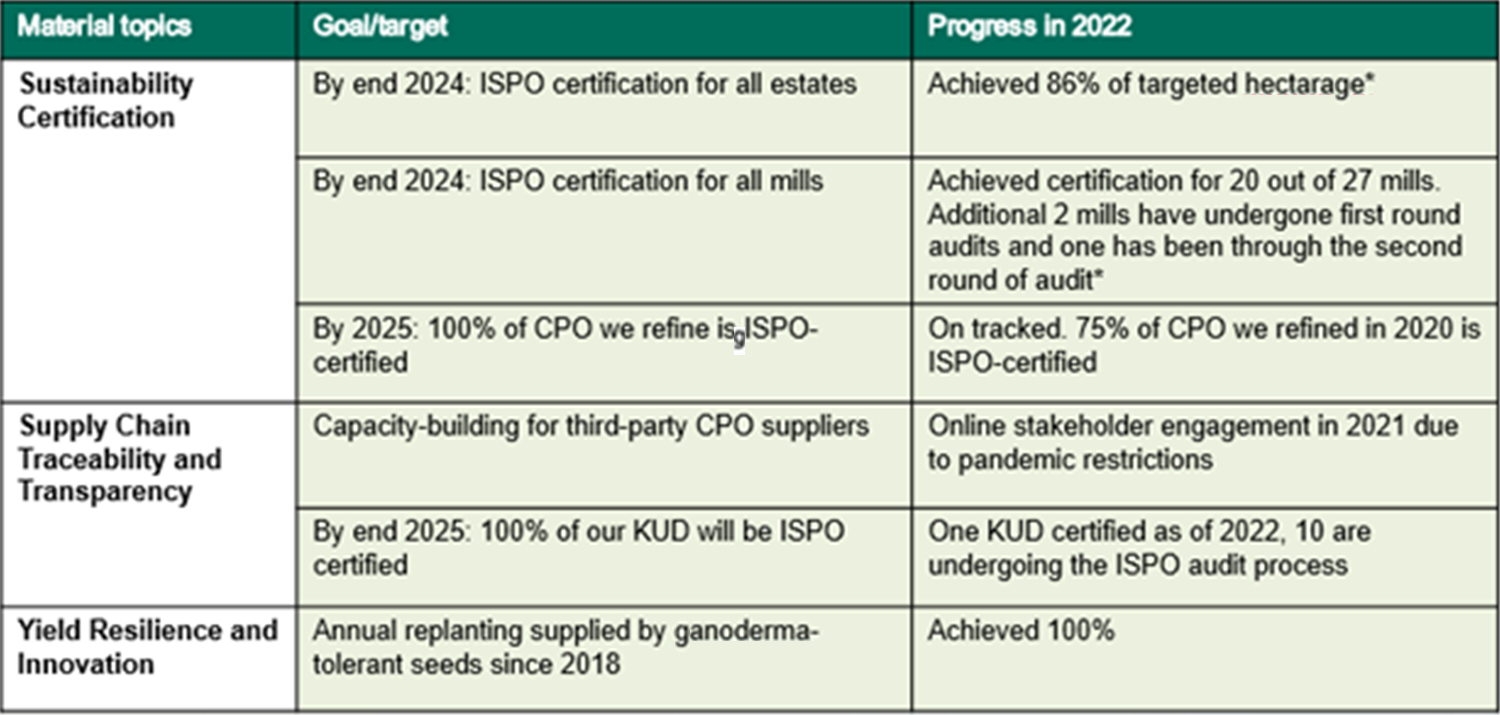

All our nucleus estates and mills are subject to certification audits; We have extended our target of achieving 100% ISPO certification to 2024 due to new areas under development. Our Policy expects CPO suppliers to achieve ISPO certification.

We encourage our suppliers, using our Responsible Supplier Guidelines, and focuses on:

|

Of all the CPO we refine, 100 % can be traced back to a supplier mill. Around 75% of CPO is sourced from our own plantations. |

Of the FFB processed at mills we control, 100% can be traced back to a plantation of origin. |

Use of Drones and UAV for monitoring of plantation operations.

In East Kalimantan, the rainy season causes flooding in our estates that hinders harvesting activities and causes soil erosion. To mitigate such risks, we map out our estates to identify the lowest lying area which acts as a catch basin, as well as drainage route. We utilize drones and unmanned aerial vehicles (UAV) to conduct extensive ground surveys that produce detailed topographic data. These technologies overcome physical restrictions and speed up the mapping process. In South Sumatra, topographic data from the drones aid us in measuring and designing terraces, roads and drainages that maintain the area’s accessibility even during heavy rains.

In North Sumatra, we use drones and UAV to identify individual trees with Ganoderma disease. Aerial pictures speed up the process of identifying and replanting diseased trees to prevent the spread of Ganoderma.

We use the ISPO certification process as part of our efforts to mitigate risk for labour, human rights, and social issues. We report that 100% of operational sites units have been formally assessed for human rights risk since 2020. The competence developed through ISPO also informs and guides our other sites which are preparing for ISPO certification. Our whistle blower mechanism yielded no alerts of Policy breaches on human rights in 2022.

All ISPO audits include criteria for assessing this risk for new suppliers.

Smallholders are crucial stakeholders in our commitment to a traceable and sustainable supply chain. In Indonesia, smallholder plantations represent at least 40% of all palm oil cultivation, they generate exports and create jobs. The Indonesian Government plans to make ISPO mandatory for smallholder farmers; we aim to support and assist our smallholders achieve the ISPO certification once it is mandated. As of 2022, one of our KUDs is ISPO certified and we are working with the rest of our smallholders.

Yield uplift is key to alleviating negative sustainability impacts. Plasma and other smallholders are expected to meet the same quality criteria as nucleus suppliers of FFB, so plasma plantations are closely aligned with our agricultural practices and management system.

If a grower is operating inefficiently it will erode their livelihood and create pressure to clear forests for agriculture. Our Smallholder Programme aims to minimise this risk. As plasma smallholders can be vulnerable to volatile market conditions, IndoAgri offers them free agronomic advice and training and makes essential resources such as seed stocks and fertilisers affordable to them using through discounts. We also help them to build the capacity of cooperatives on the journey to achieving ISPO certification. Our engagement with smallholders also involves training and workshop activities on sustainable palm oil.

A key target is for our mills and nucleus plantations to become ISPO-certified by 2024.

* Figures cover hectarage or number of mills that are already certified or have completed ISPO first stage audit. The certificate release date is subject to the accreditation period of the certifying body. Certified hectarages data performance compared to base year 2020.

IndoAgri's experienced laboratory team account for food safety risk while working on specific product formulations to meet evolving needs of customers. Our Quality Control teams undergo regular management training on hygiene, safety and Halal risk and control. They are at the heart of our product quality assurance.

An approved Halal certification system applies to all our products and refineries, it is accredited to LPPOM MUI, The Assessment Institute for Foods, Drugs And Cosmetics, the Indonesian Council of Ulama.

Marketing.

IndoAgri was proud to contribute cooking oil to the Ministry of Trade’s “MINYAKITA” cooking oil brand in 2022. We consistently support and participate in fulfilling the needs of DMO (Domestic Market Obligation) packaged cooking oil in accordance with the volume allocation determined by government.

With increasing digitalization efforts and elements of COVID-19 restrictions persisting in 2022, we engaged our customers through social media channels. Our cooking demos were hosted weekly on our Instagram page, @Palmia _ID, and were well-received by individual consumers and SMEs. We continued to publish recipes on our website; an initiative that has also performed well.

* Big Five refer to the top five raw material suppliers based on raw material tonnage supplied to our

refineries

** During the pandemic, self-assessment audits were conducted